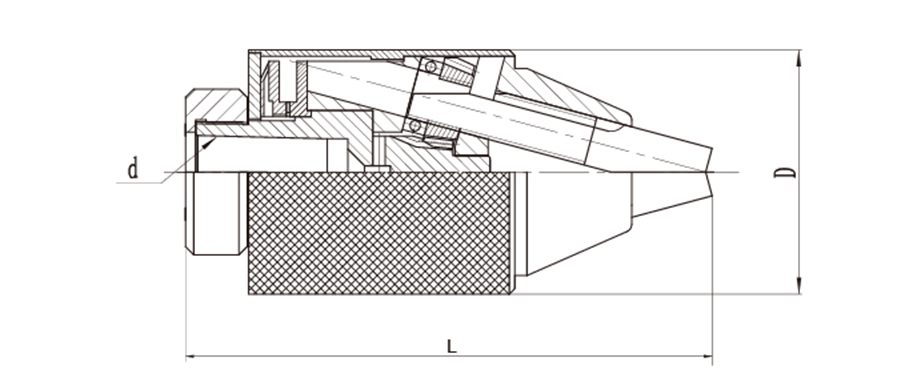

| ihe nlereanya | nha | Oke njigide | Oke igwu mmiri | Oke ịpị | D | L | |||||

| ihe nlereanya | Ugwu | mm | in | mm | in | mm | in | mm | in | mm | in |

| J0113M-B12 | B12 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| J0113M-B16 | B16 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| J0113M-JT2 | JT2 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| J0113M-JT33 | JT33 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| J0113-B16 | B16 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 118 | 4.646 |

| J0113-JT33 | JT33 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 118 | 4.646 |

| J0113-JT6 | JT6 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 118 | 4.646 |

| J0116-B16 | B16 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

| J0116-B18 | B18 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

| J0116-JT33 | JT33 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

| J0116-JT6 | JT6 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

Taper mount tapping and drilling self-tighting chucks bụ ngwá ọrụ pụrụ iche nke a na-eji na-ejido ma chekwaa olulu mmiri na mmiri n'ebe a na-arụ ọrụ machining.Nkịta ndị a bụ ihe dị mkpa nke nhazi igwe ọ bụla ma ejiri ya mee ihe n'ọtụtụ ọrụ dị iche iche, gụnyere ikuku ikuku, ụgbọ ala, na nrụpụta.

Nrụpụta steepụ nke taper chuck dabere na usoro Morse taper, nke bụ usoro ahaziri ahazi nke ichekwa ngwaọrụ n'ime mkpịsị igwe.Taper ugwu chucks na-egosipụta a nwoke taper e mere ka dabara snugly n'ime a kwekọrọ ekwekọ nwaanyị taper na igwe spindle.Nke a na-enye njikọ echekwabara ma kwụsie ike nke na-eme ka nhazi ngwa ọrụ ziri ezi ma na-ebelata ngwa ngwa runout.

Otu n'ime uru bụ isi nke taper mount chucks bụ ntụgharị ha.Ndị a chucks nwere ike ijide ụdị ngwá ọrụ dị iche iche na nha, gụnyere ntanye egwu, taps, reamers, na igwe igwe njedebe.Nke a na-eme ka ha dị mma maka ngwa igwe dị iche iche, site na ịkụ ala na ịkụ aka ruo na-agwụ ike na igwe igwe.

Taper mount chucks dị n'ụdị nha na ụdị dị iche iche iji kwado ihe igwe dị iche iche chọrọ.Standard taper ugwu chucks a na-emekarị ka dabara n'ime Morse taper na igwe spindle, mgbe ogologo taper ugwu chucks atụmatụ ogologo tapers maka mụbaa rigidity na izi ezi.A na-enwekwa chucks taper na-agbanwe ngwa ngwa, nke na-enye ohere maka mgbanwe ngwa ngwa na-enweghị mkpa maka ngwaọrụ ma ọ bụ ngwa ndị ọzọ.

Na mgbakwunye na ha versatility na mfe nke ojiji, taper mount chucks na-mara maka ogologo ha na ntụkwasị obi.A na-ejikarị ihe ndị dị oke mma eme chucks ndị a, dị ka ígwè siri ike ma ọ bụ carbide, ma emebere ya ka ọ nagide ihe siri ike nke ọrụ igwe dị arọ.Ha dịkwa obere na-arụkwa ọrụ nke ọma ma na-achọ nlekọta dị ntakịrị iji hụ na arụmọrụ na-adịte aka.

Mgbe ị na-eji taper mount chuck, ọ dị mkpa iji hụ na ntinye ngwá ọrụ kwesịrị ekwesị na ntinye aka iji zere ngwa ngwa ngwa ngwa ma belata ihe ize ndụ nke imebi chuck ma ọ bụ spindle igwe.Nke a na-agụnye nke ọma itinye ngwa ahụ n'ime chuck na imechi agbà chuck iji chekwaa ngwá ọrụ ahụ.Ọ dịkwa mkpa ka ị na-enyocha chuck mgbe niile maka iyi na mmebi na iji dochie ihe ọ bụla eyighị ma ọ bụ mebiri emebi dị ka ọ dị mkpa.

N'ozuzu, taper mount tapping na drilling chucks na-ejide onwe ya bụ ihe dị mkpa maka ịrụ ọrụ igwe ọ bụla.Ha na-enye njikọ dị nchebe ma kwụsie ike maka ọtụtụ ngwá ọrụ dị iche iche, na ntụgharị ha na ịdịte aka ha na-eme ka ha dị mma maka ngwa dị iche iche.Site n'ịhọrọ ezigbo taper mount chuck maka mkpa machining gị kpọmkwem yana ịgbaso usoro nhazi na nhazi kwesịrị ekwesị, ị nwere ike hụ na arụmọrụ a pụrụ ịdabere na ya na-agbanwe agbanwe maka afọ ndị na-abịa.